Structural Fabrication

AWS D1.1 Certified | Structural Steel | AISC Practices | OSHA Compliant

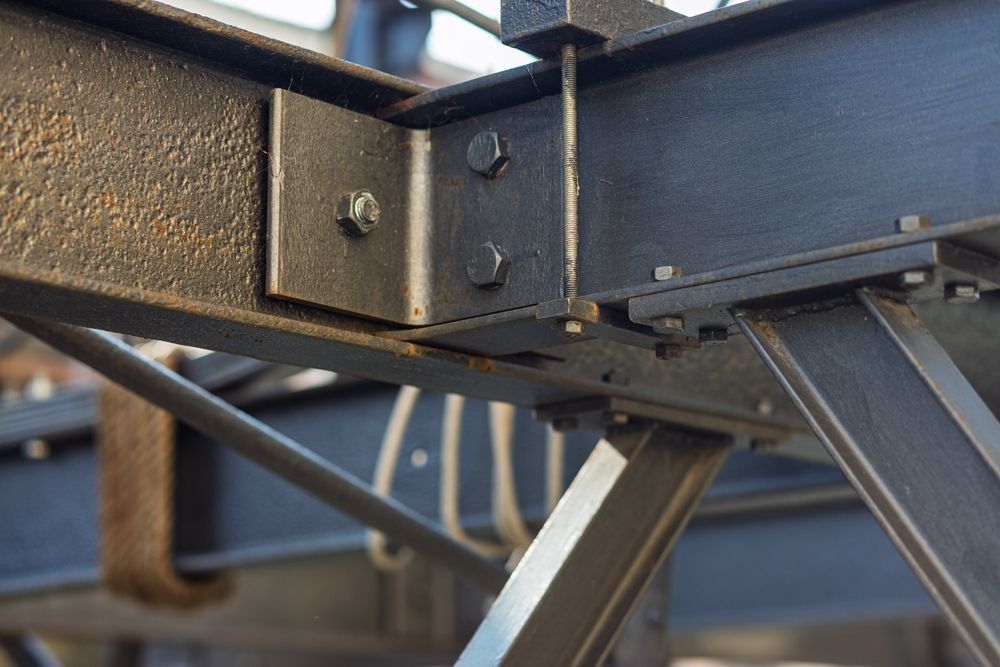

Structural Steel Capabilities

- Beams, columns, and primary framing members

- Plates, embeds, and connection components

- Structural tube and custom profiles

- Reinforcement and strengthening of existing steel

- Corrective fabrication and structural modifications

Fabrication Process

- Shop drawing review and coordination

- Material verification and layout

- Controlled fit-up and dimensional checks

- AWS D1.1–certified welding procedures

- Structural alignment and quality verification

Welding & Quality Control

- AWS D1.1–Certified structural steel welding

- Qualified welders with continuity tracking

- Visual weld inspection and fit-up verification

- Repair welding performed to approved procedures

Codes & Standards

- AWS D1.1 Structural Welding Code (Steel)

- AISC-referenced structural steel practices

- OSHA-compliant shop and field operations

- DOT and federally referenced requirements supported when specified

Integration With Surface Preparation & Coatings

- Fabrication coordinated with abrasive blasting and coating scopes

- Structural prep supporting corrosion protection requirements

- Retrofit fabrication aligned with existing steel and surface conditions

Project Types

- Commercial & High-End Residential buildings

- Industrial facilities

- Federal, state, and municipal projects

- Military and defense-related facilities

- Structural repairs and retrofit projects

Service Area

- Supporting structural steel projects across New England and New York