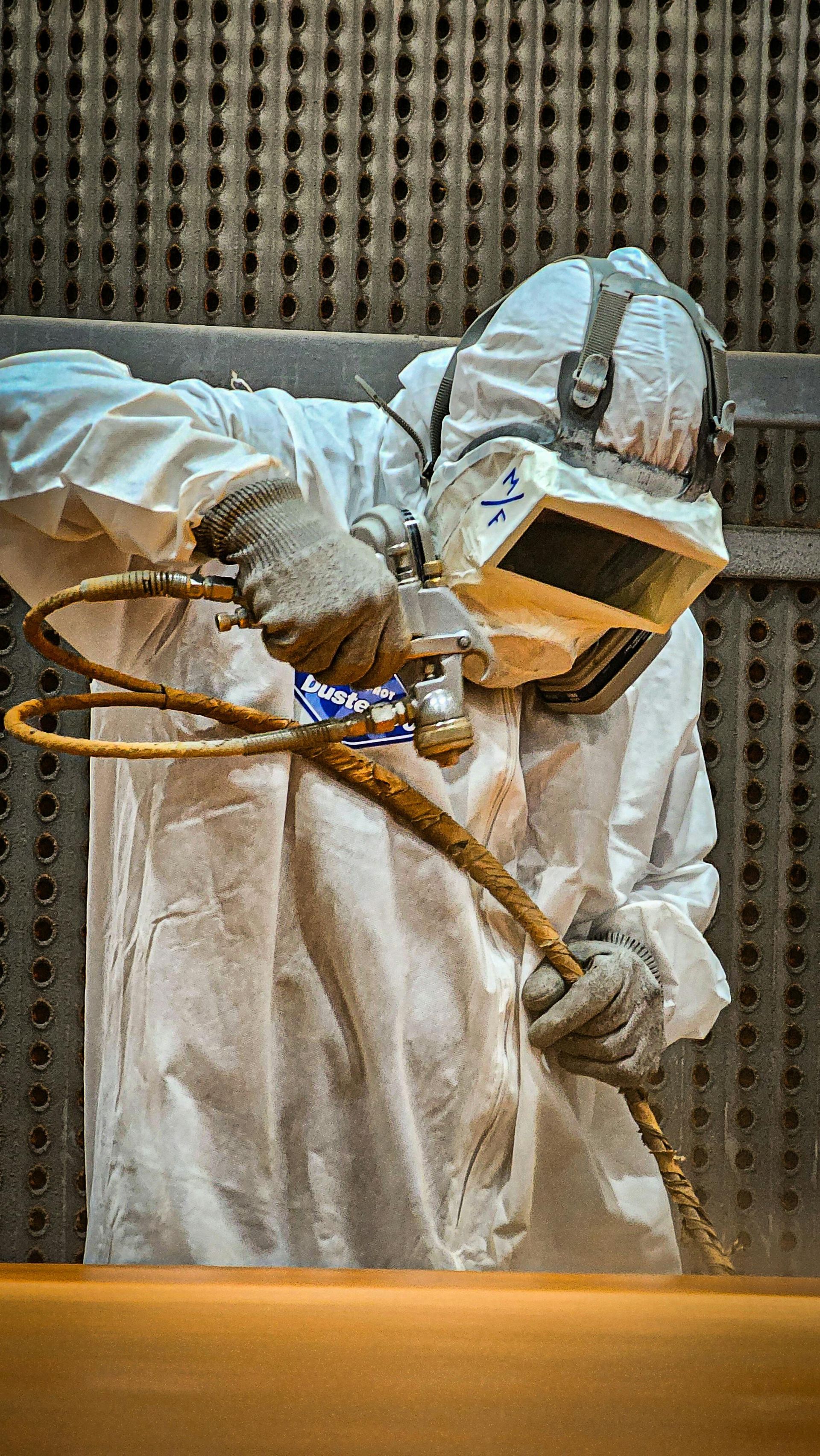

ABrasive blasting

Controlled Surface Preparation for Coating, Fabrication, and Asset Restoration

What We Support

- Structural steel and fabricated components

- Fleet vehicles and equipment

- Industrial and infrastructure assets

- Custom metal projects

- New fabrication, refurbishment, and recoating work

Blasting Services

- Abrasive blasting for surface cleaning and preparation

- Removal of rust, mill scale, coatings, and contaminants

- Blasting to project-specified cleanliness levels

- Surface preparation for primers and protective coatings

- Blasting of fabricated steel and assemblies

- Asset refurbishment prior to finishing

- Controlled blasting to protect critical surfaces

Abrasive & Media Options

- Grit blasting

- Steel grit and steel shot

- Slag abrasives

- Garnet

- Aluminum oxide

- Glass bead

- Specialty and non-aggressive media

- Controlled and low-pressure blasting

Standards & Project Requirements

- Surface preparation performed to project specifications

- Work aligned with AMPP / SSPC surface preparation guidelines when specified

- MIL-SPEC surface preparation requirements supported when required

- Surface profile matched to coating system requirements

- Experienced Technicians

Quality Control

- Surface profile checked with calibrated gauges

- Visual cleanliness verified to project criteria

- Clean, dry, conditioned compressed air

- Trained blasting technicians

- Controlled work environments when required

- Documentation supporting inspection and coating scopes

Integration With Fabrication & Coatings

- Blasting coordinated with fabrication and welding work

- Surface prep aligned with coating and finishing scopes

- Support for industrial, architectural, and protective systems

Where We Work

- Abrasive blasting services across New England and New York based in Pittsfield MA